cnc lathe machine operation procedure In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece . How do I size a junction box. Not for pulls, but for conductor fill of 4awg and larger. I'm basically going to be splicing two 4-3 ser cables and will do it in a 6" box but I'd like to .

0 · turning operations on lathe machine

1 · turning operation lathe

2 · turning lathe diagram

3 · cnc turning lathe machine

4 · cnc lathe setup

5 · cnc lathe machine operations

6 · basic turning operations

7 · application of cnc lathe machine

One of the best places to get started is in your home—where a surprising number of items can be contaminated with heavy metals. 1. Carpet and Area Rugs. It may feel soft underfoot, but one of the sources of heavy metal exposure in your home is through your carpet.

1.1 Add appropriate lubricating oil and grease according to the machine lubrication chart. 1.2 Check that all electrical facilities, handles, transmission parts, guards, and limit devices are complete, reliable, and flexible. 1.3 All gears should be in the neutral position, and the belt tension should meet the requirements. 1.4 . See more2.1 Properly secure the workpiece, start the lubricating oil pump first, and ensure that the oil pressure meets the machine’s specifications before starting. 2.2 When adjusting the gear box or hanging wheel, the power supply must be disconnected. After adjustment, all . See more

4.1 Non-personnel are strictly prohibited from operating the machine. 4.2 It is strictly prohibited to touch the tools or any rotating parts of the machine during operation. 4.3 Use . See more

3.1 Cut off the power and remove the workpiece. 3.2 Reset all handles to the zero position, and clean and tidy up the tools and equipment. . See more In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece .

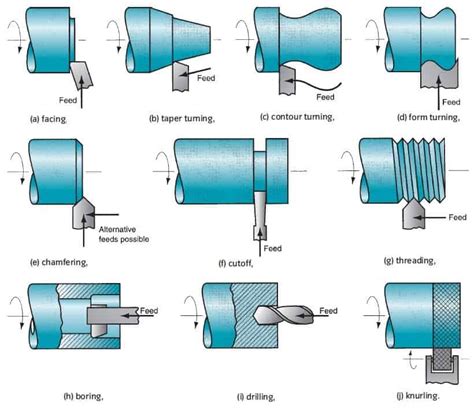

Ever wondered how to safely and efficiently operate a lathe? This article breaks down the essential procedures and precautions every operator must follow. From pre-operation inspections to precise shutdown protocols, it covers all . In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.

turning operations on lathe machine

Below, we explain CNC lathe machine operation. A lathe can be used for shaping metals, alloys, plastics, or even different types of wood. It’s based on moving unwanted material to shape a workpiece by using a stationary cutting tool around which the workpiece revolves.

WORKSHOP MACHINES - LATHE • All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. • Use the correct sized clamp or vise for the stock being machined. • Turn the chuck or faceplate by hand to ensure there is no binding or danger of the work striking any part of the lathe. What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.

This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup

With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.

turning operation lathe

ClickUp's CNC Lathe Machine SOP Template is designed to help you create and maintain standard operating procedures for CNC lathe machine operations. This Doc template contains all the necessary sections and content to guide your team through the .

Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control. Start and home a CNC machine. Load tools into tool carousel. Set Tool Length Offsets. Set Part Offsets. Load a CNC program into the machine control. Safely run a new CNC program. What is CNC lathe Machine? A CNC lathe (CNC turning machine) is a machine that spins material around a central spindle and a fixed cutting tool. Instead of being controlled by physical labor, the movement of your components is determined by .

Ever wondered how to safely and efficiently operate a lathe? This article breaks down the essential procedures and precautions every operator must follow. From pre-operation inspections to precise shutdown protocols, it covers all . In this article, you will learn about what are the different types of lathe machine operations performed on the lathe machine. A lathe is a machine that rotates the workpiece about an axis to perform different operations such as turning, facing, taper turning, knurling, grooving, parting off, thread cutting, reaming, etc.

Below, we explain CNC lathe machine operation. A lathe can be used for shaping metals, alloys, plastics, or even different types of wood. It’s based on moving unwanted material to shape a workpiece by using a stationary cutting tool around which the workpiece revolves.WORKSHOP MACHINES - LATHE • All stock must be properly secured in the lathe chuck or mounted prior to the machining process taking place. • Use the correct sized clamp or vise for the stock being machined. • Turn the chuck or faceplate by hand to ensure there is no binding or danger of the work striking any part of the lathe.

What are the different operations that can be performed on a lathe machine? Here we’ll go through the types of the basic machining processes on a CNC lathe.This standard operating procedure (SOP) provides comprehensive guidelines for operating a CNC machine and outlines the key steps to be followed during machine setup, programming, and maintenance. Step 1: Machine Setup With a CNC lathe, the tooling operates according to a program written and uploaded to the machine, allowing for highly precise and repeatable production. How does a CNC lathe work? Read on to learn the answer — as well as some tips for operation in the process.ClickUp's CNC Lathe Machine SOP Template is designed to help you create and maintain standard operating procedures for CNC lathe machine operations. This Doc template contains all the necessary sections and content to guide your team through the .

turning lathe diagram

Understand the CNC Operation. List the steps to set up and operate a CNC mill. Identify the location and purpose of the operating controls on the Haas CNC Mill control. Start and home a CNC machine. Load tools into tool carousel. Set Tool Length Offsets. Set Part Offsets. Load a CNC program into the machine control. Safely run a new CNC program.

can you use romex in metal boxes

can you weld zinc coated sheet metal

If you’re looking to make money off of the old items around your home, you might be wondering what scrap metal is worth the most money to sell right now. We’ve put together the top list of nine things people should consider scrapping for maximum profit:

cnc lathe machine operation procedure|turning lathe diagram